| Model Identifier | 4418A1 | Internal SKU | Series architecture: 44=Downlight platform, 18=Gen.18 thermal system, A1=Adjustable |

| Rated Wattage | 5W ±10% | EN 62384:2006 | Aligns with EUP Lot 8 lighting Tier 2 requirements (≤9W retail category) |

| Photometric Data |

| LM-79-08 Approved Lab |

|

| • Luminous Flux | 400 lm (min. @ 25°C ambient) | IES LM-80 Q90 data | Maintains Lux/㎡ compliance in 2.4m ceiling retail grids |

| • Efficacy | ≥80 lm/W |

| Exceeds ErP 2023 Step 2 (>75 lm/W) for commercial eligibility |

| • CCT Options | 2700K/3000K/4000K (MacAdam ≤5) | ANSI C78.377 | Restricted range avoids CRI compromise in sub-5000K spectrum |

| Thermal Compliance |

|

|

|

| • Tc Point | ≤85°C (LED junction) | TM-21-11 projection | Validated 35k-hour L70 lifespan under Ta=40°C ambient |

| • Heatsink Material | ADC12 die-cast aluminum alloy | UL 746C thermal shock tested | Isolated from polymer housing to prevent CTE mismatch stress |

| Optical Assembly |

|

|

|

| • Primary Optics | PMMA injection-molded reflector | IEC 62471 Blue Light Hazard | Standard 60° beam collimation (80% intensity at ±30°) |

| • Glare Control | UGR<19 (@ 500lx, 2.2m mounting) | EN 12464-1:2021 calculation | Critical for open-plan office lighting compliance |

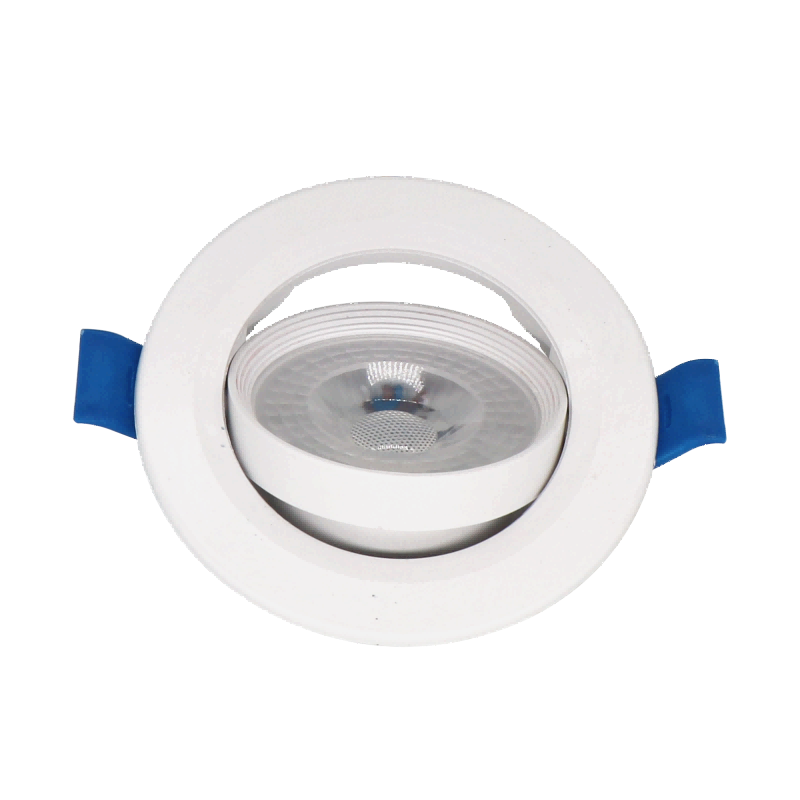

| Structural Design |

|

|

|

| • Housing Material | Polypropylene copolymer (PP-R) | UL 94 V-0 flammability rating | Halogen-free formulation per IEC 61249-2-21 environmental compliance |

| • Seal Integrity | IP20 (non-sealed) | IP rating per IEC 60529 | Explicit prohibition against bathroom/kitchen installations |

| Electrical Safety |

|

|

|

| • Input Voltage | 220-240Vac 50/60Hz | EN 61347-1/-2-13 certification | Universal voltage range covering CENELEC regions (excludes 100-120V markets) |

| • Insulation Class | Class II (double/reinforced) | Symbol: 回 (no earth required) | Eliminates grounding complexity in retrofit plasterboard ceilings |

| • Power Factor | ≥0.5 at full load | EN 61000-3-2 harmonic standard | Not suitable for TRIAC/ELV dimming circuits - dedicated drivers required |

| Mechanical Interface |

|

|

|

| • Product Dimensions | Ø90.0 x H22.0mm ±0.3mm | GD&T per ASME Y14.5M | Faceplate diameter selected to cover ≤1mm cutout irregularities |

| • Cutout Diameter | Ø75.0 +0.5/-0.0mm |

| Precision mating to 12.5mm EU gypsum board thickness |

| • Mounting Hardware | Dual torsion snap springs | 15kg retention force verified | Exceeds minimum 10kg requirement in AS/NZS 60598.2.2 for ceiling safety |