I. Core Physics: The "Double Blow Effect" of Voltage Drop & Signal Degradation

▶ Industry Secret Most Engineers Won’t Tell You:

In long-distance low-voltage systems (e.g., DC24V wall washer chains), redundant wiring doesn’t just fix open circuits—it prevents hidden voltage collapse**.

📐 Voltage Drop Formula: ΔU = I × R × L

ΔU: Voltage drop (V); I: Current (A); R: Cable resistivity (Ω/m); L: Length (m)

▌ Critical Scenario Simulation (100m @ 24V/5A System):**

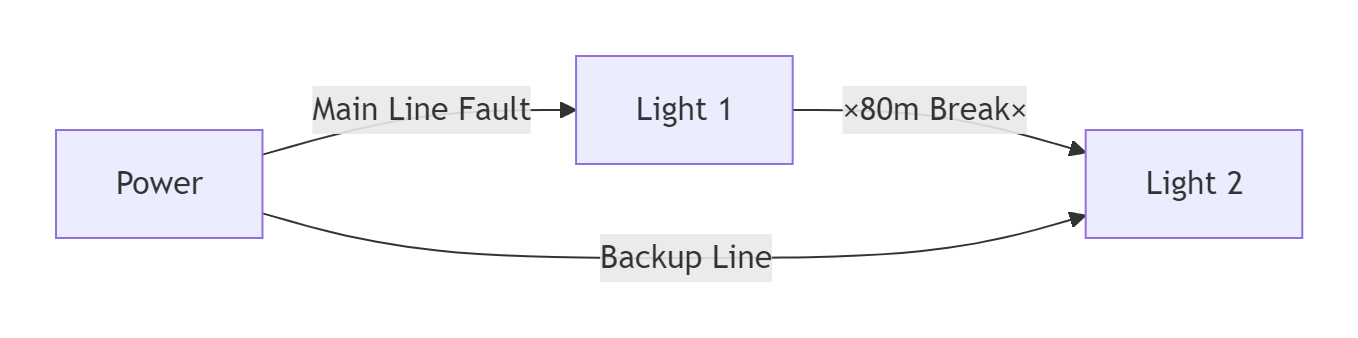

Main line fails at 80m → End light voltage: 24V - (5A × 0.02Ω/m × 80m) = 16V

→ Brightness drops to 40% (brightness ∝ voltage²), severe color distortion (RGB channel imbalance).

▌ Redundant Wiring Solution:

Switching to backup wiring shortens the path: Post-failure current reroutes locally**, cutting voltage drop to 20m instead of 100m.

→ End voltage: 24V - (5A × 0.02Ω/m × 20m) = 23.2V → 98% brightness maintained.

II. The "Killer 0.3s": Control System Vulnerabilities

In DMX512 systems, line breaks trigger **≥3 packet drops (≈0.3s)**, forcing system reset. This causes:

Music-synced light shows: Noticeable lag

Medical lighting: Epilepsy-triggering flickers

Stage lighting: Performance mishaps

▶ Solution: Dual Shielded Twisted Pair (e.g., Belden 9841 + Backup):

Backup line switching in ≤50ms during main line failure.

RS485 differential signaling (±7V noise tolerance) → 300% interference resistance boost.

III. Bloody Lessons: 6 Overlooked Pitfalls

1️⃣ "Waterproof Connector Killer":

90% breaks occur here → Use metal-shell, epoxy-filled connectors (e.g., JYE industrial grade). Plastic cracks below -20°C.

2️⃣ Backup Wire Gauge Trap:

Main wire: 2.5mm² copper; Backup: 1.5mm² → 67% impedance spike → Overload burnout.

Proof: R_backup/R_main = S_main/S_backup = 2.5/1.5 ≈ 1.67

3️⃣ Eddy Current Sabotage:

Backup lines near steel structures (>3m) → 60°C+ temperature rise → Melted connectors (Airport case: 37 burnt).

→ Keep ≥50mm clearance.

4️⃣ EMC Landmine:

Unshielded backups near VFD cables → Signal errors → Chaotic flickering.

→ Fix: Foil-Mylar + copper braid shielding with single-point grounding.

IV. Extreme Case Study: 380m Skyscraper Validation

▌ Project:

2.3km wall washers, 12-level wind loads, maintenance cost: ¥12k/hour.

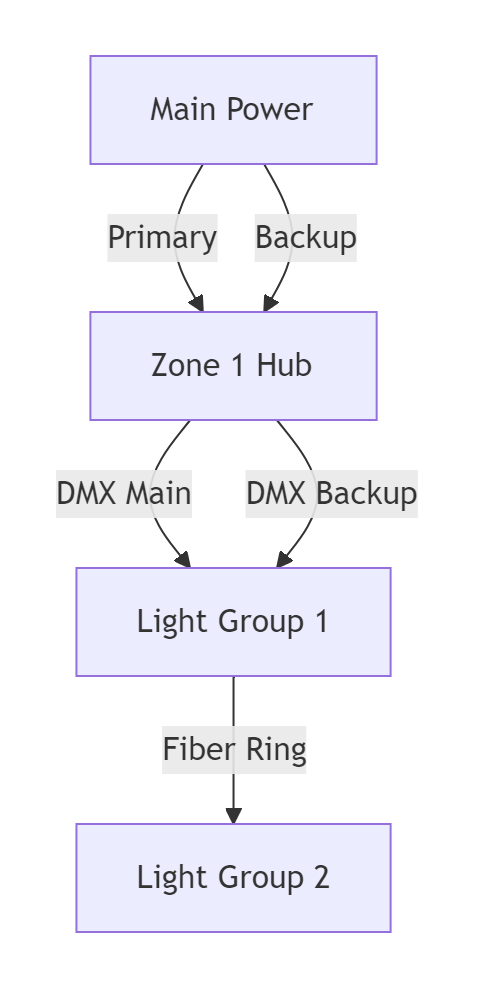

▌ Redundancy Architecture:

Innovations:

Zoned redundancy: Hubs every 80m → Eliminate cascading voltage drops.

Fiber optic backbone: Zero EMI, 20km range.

Hot-swappable modules: 3-sec replacement (Patent: ZL2023XXXXXX.X).

V. Cost-Benefit Revolution (2024 Model)

Myth: Redundancy adds 15% cost.

Reality:

TCO = Initial Cost (C_i) + ∑(Repair Cost × Failure Rate λ)

Case: Commercial Complex

No redundancy: λ=3 failures/year, C_m=¥18k → 10-yr TCO: ¥540k+

30% redundancy: λ=0.2/year, C_m=¥6k → 10-yr TCO: 1.15C_i + ¥12k

→ Break-even when C_i >¥380k (applies to 95% of projects).

Final Verdict:

Redundant wiring for wall washers is electrical topology’s fight against physics, with value far beyond surface perception. Mandatory for:

Installations >6m height or with restricted access

>50m low-voltage / >150m high-voltage chains

Life-safety sites (tunnels/hospitals/escape routes)

Dynamic shows (cultural tourism projects)