🔥 1. Thermal Management Design (Core Difference)

Traditional Driver Solution

The driver circuitry is physically isolated from the LED light source, eliminating shared thermal pathways. Temperature-sensitive components (e.g., electrolytic capacitors, MOSFETs) operate below 75°C, aligning with their design limits (e.g., electrolytic capacitor lifespan doubles for every 10°C drop, per the Arrhenius equation).

DOB (Driver-on-Board) Solution

Driver circuits are integrated directly onto the aluminum substrate, sharing thermal paths with LEDs. Typical operating temperatures exceed >90°C, causing:

Exponential degradation of electrolytic capacitors (lifespan halves per 10°C rise);

Magnetic components (inductors/transformers) suffer reduced saturation current, dropping efficiency by 5–10%;

PCB copper impedance shifts increase current fluctuation.

Case Study: Void-filled solder layers or poor die-attach quality in DOB further escalate thermal resistance, accelerating device aging.

⚡ 2. EMC Performance

Traditional Driver Solution

Metal enclosures provide EMI shielding and accommodate multi-stage filtering (X/Y capacitors, common-mode chokes), effortlessly passing Class B EMC tests with robust suppression of radiated (RE) and conducted emissions (CE).

DOB Solution

High-frequency switching circuits (e.g., Buck topology) are exposed on the PCB:

Prone to harmonic interference (150kHz–30MHz);

60% risk of RE violations due to absent shielding;

Requires added filters/magnetic rings, increasing complexity.

Data: DOB exhibits 15–20dB higher EMI noise at 30–100MHz in lab tests.

⚡ 3. Electrical Stress Tolerance

| Parameter | Traditional Driver | DOB Solution |

|---|---|---|

| Input Voltage Range | 85–305V AC | 180–260V AC |

| Surge Test (4kV) Pass Rate | >95% | <40% |

DOB’s compact PCB limits space for large MOV varistors, weakening surge protection. Traditional drivers integrate multi-stage circuits (e.g., gas discharge tubes + TVS diodes).

Mains-Frequency Flicker

DOB relies on valley-fill capacitors to suppress 100Hz flicker, but capacitor failure exacerbates flicker. Traditional drivers eliminate flicker via high-frequency switching (>20kHz).

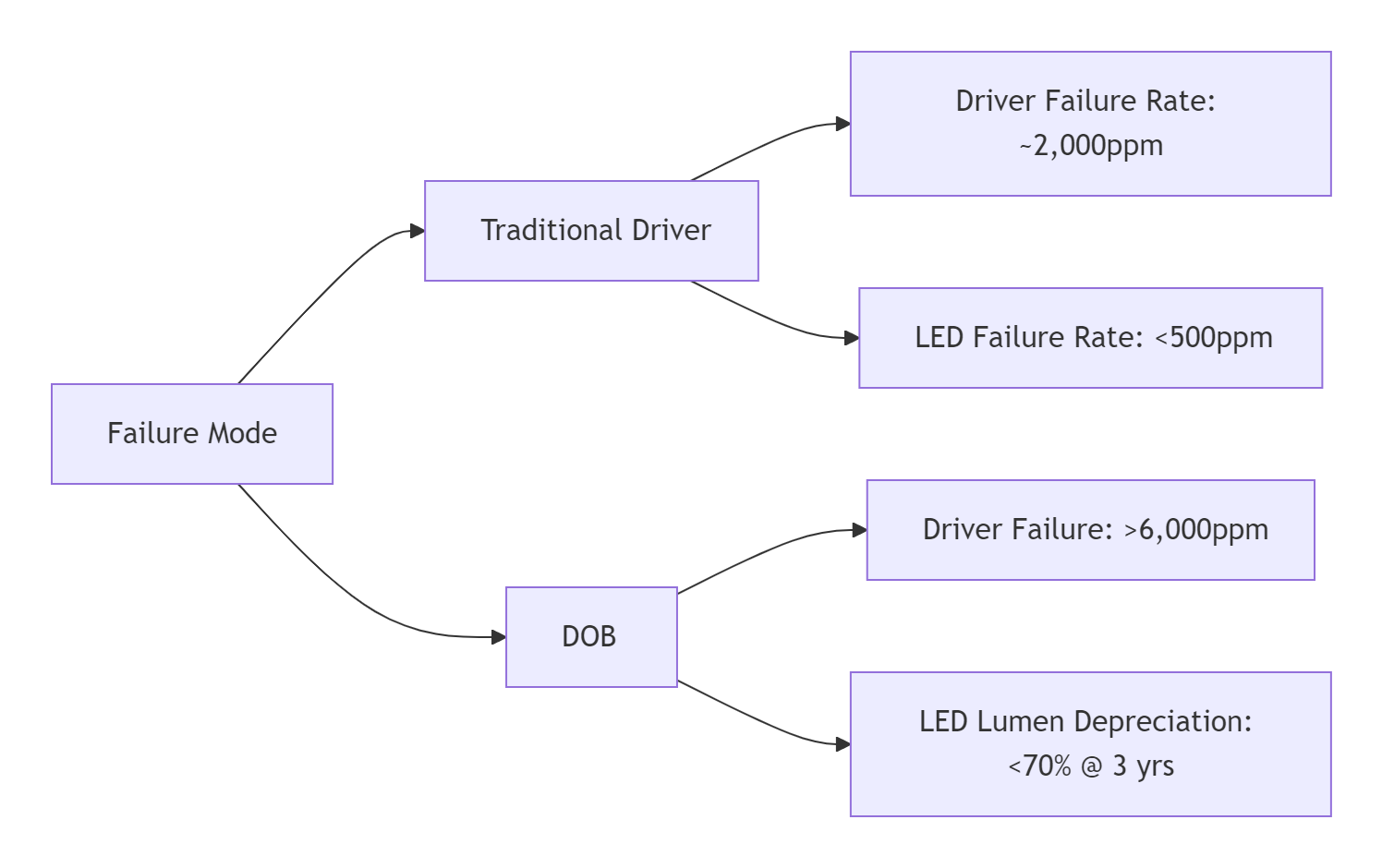

🛠️ 4. System Reliability Comparison

Key Factors:

DOB electrolytic capacitors last 10k–20k hours at high temps vs. >50k hours in traditional drivers;

DOB integration forces full fixture replacement (near 100% repair cost), while modular drivers cost <30% to replace.

🔄 5. DOB Improvements & Limitations

Despite stability enhancements, inherent flaws persist:

Electrolytic-free designs: Use MLCC capacitors but increase cost by 50–80% with limited capacitance;

Thermal interface upgrades: High-conductivity pads (>6W/m·K) partially mitigate shared heat but fail to resolve core issues;

Smart IC protection: Current throttling under overheating restricts power to ≤15W, narrowing applications.

💎 Conclusion & Selection Guidelines

| Specification | Traditional Driver | DOB Solution |

|---|---|---|

| Applications | Engineering lighting, >50kh lifespan | Low-cost, low-power (<15W) fixtures |

| Stability Advantages | Thermal isolation, EMC shielding, wide voltage range | Compact size, low cost |

| Recommended Use Cases | Outdoor/industrial/tunnel lighting | Household bulbs/downlights |

Summary: Traditional drivers excel in thermal management, electrical robustness, and maintainability through physical isolation, independent EMC shielding, and modular design. DOB, despite cost/size benefits, remains constrained by component longevity and stability at high temperatures.