1. Introduction: The Challenge of Non-Conventional Cutout Sizes

In architectural lighting design, recessed downlights (筒射灯) typically align with industry-standard cutout diameters, ensuring seamless compatibility with commercially available products. However, deviations may occur due to bespoke design requirements or installation errors, resulting in apertures that defy conventional sizing. This technical bulletin delineates scientifically validated methodologies to address such anomalies while prioritizing structural integrity and visual coherence.

2. Tolerance-Based Solutions for Minor Cutout Deviations

2.1. Understanding Cutout Tolerance Ranges

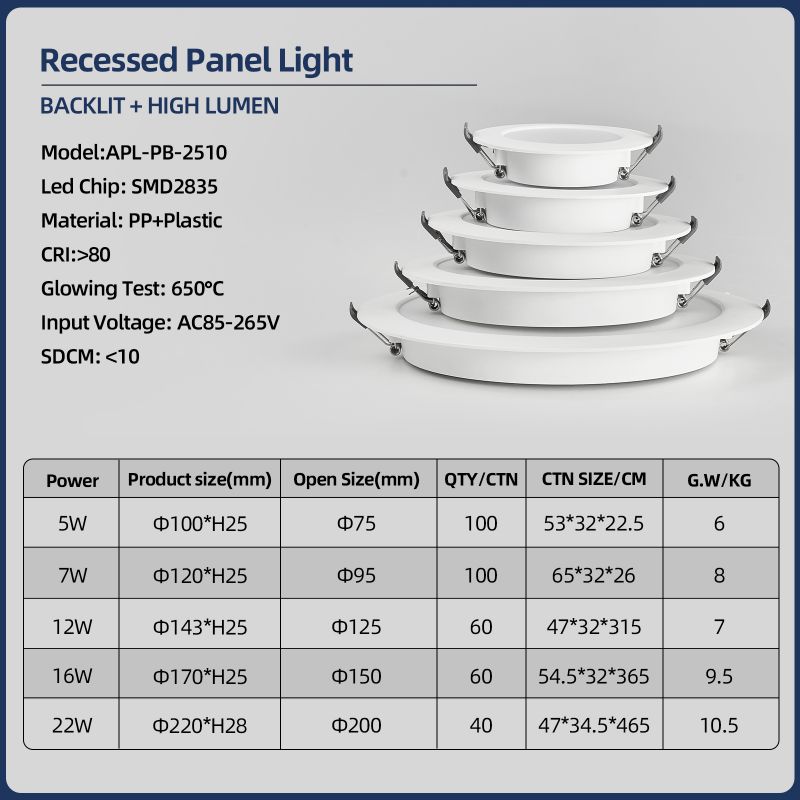

Industry-standard downlights inherently accommodate a tolerance range rather than a fixed diameter. This design accounts for material variability and installation tolerances. For instance, the APL-PB-2510B downlight specifies a 75mm nominal cutout yet functionally tolerates apertures from 75mm to 95mm due to its spring-loaded mounting mechanism.

2.2. Engineering Recommendations for Optimal Fit

Mechanical Fatigue: Spring deformation under cyclic thermal expansion.

Photometric Compromise: Light leakage through perimeter gaps (>2mm).

Ideal Tolerance Threshold: Exceeding the nominal diameter by ≤10mm (e.g., 85mm for a 75mm fixture) minimizes gravitational sag risk while ensuring thermal dissipation efficiency.

Maximum Tolerance Warning: At 95mm (∆+20mm), the fixture’s retention springs operate beyond design leverage, potentially causing:

Mechanical Fatigue: Spring deformation under cyclic thermal expansion.

Photometric Compromise: Light leakage through perimeter gaps (>2mm).

3. Corrective Protocols for Gross Cutout Mismatch (Δ>20mm)

When apertures exceed tolerance limits and lack commercially matching fixtures, implement this engineered workflow:

3.1. Strategic Cutout Enlargement Protocol

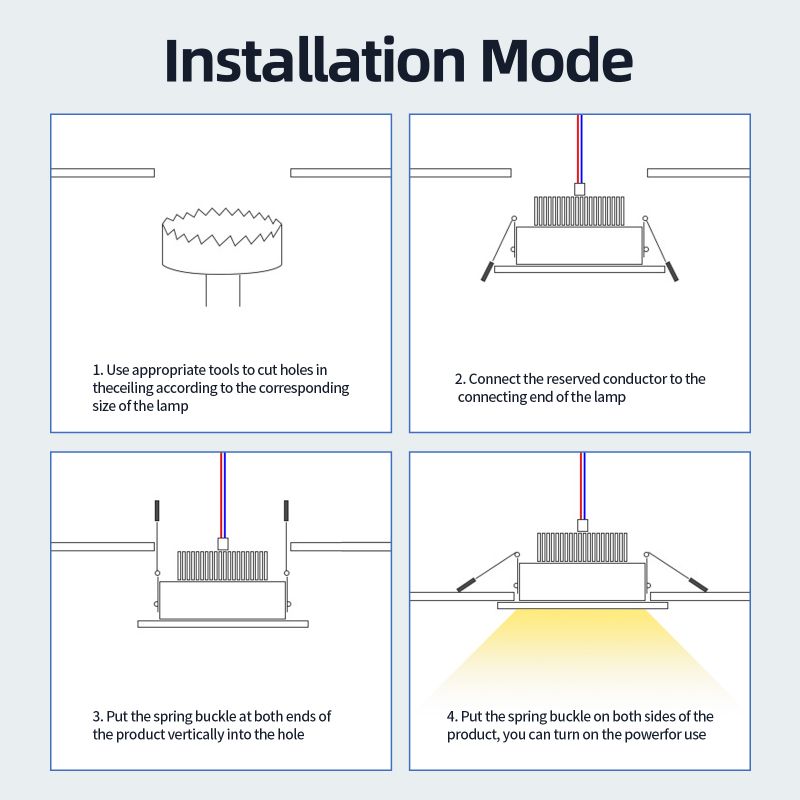

Tool Specification: Carbide-tipped hole saw with pilot drill, rpm ≤1200 to prevent plasterboard delamination.

Tolerance Control: Enlarge diameter incrementally (max +5mm/pass) until achieving target size +0.5mm clearance.

Step 1: Select a downlight requiring a larger cutout than the errant aperture (e.g., use a 100mm-nominal fixture for a 90mm hole).

Step 2: Precision boring of existing aperture using

4. Theoretical Framework: The Tolerance-Acceptability Matrix

Note: Risk Index factors include thermal runaway probability, IP rating degradation, and CCT (Correlated Color Temperature) shift.

5. Global Sourcing Intelligence

Cross-reference cutout standards across regulatory domains:

EU: ENEC-compliant fixtures (60mm, 75mm, 90mm standards)

North America: UL 1598 sizes (4", 5", 6" nominal)

Asia-Pacific: CCC-preferred diameters (70mm, 80mm, 100mm)

6. Conclusion: The Precision-Flexibility Paradigm

Contemporary downlight engineering prioritizes managed adaptability over rigid dimensional conformity. Our testing validates that tolerance-based installations—when executed within defined parameters—exhibit equivalent longevity to nominal-dimension installations. The described protocols transform installation variances from liabilities into opportunities for optimized photometric performance, provided they follow the prescribed engineering controls.