Revolutionizing Heritage Illumination

DC24V The Advanced LED Corrugated Light LY-WLD-7005

In the specialized domain of architectural lighting, particularly for culturally significant structures, the advent of the LED Corrugated Tile Light marks a significant leap forward. This innovative luminaire is meticulously engineered to address the unique challenges of illuminating ancient buildings, historical landmarks, and any structure featuring traditional tiled roofs – think temples, pagodas, castles, museums, heritage districts, and boutique resorts. Combining cutting-edge LED technology with thoughtful design, these lights offer an unparalleled blend of compact size, effortless installation, intrinsic safety, exceptional value, and tailored aesthetics, making them the definitive choice for heritage and tiled architectural projects worldwide.

Core Advantages for Heritage Applications:

1. Minimalist Profile & Stealth Integration:

The defining characteristic of LED corrugated lights is their remarkably compact size and low profile. Engineered to be virtually invisible when installed, they nestle discreetly beneath the ridges of traditional corrugated tiles or curved roof elements.

This minimal visual intrusion is paramount for heritage conservation. The lighting effect – a gentle, controlled wash highlighting the beautiful contours and textures of the tiles or roof structure – becomes the focus, not the fixture itself. It preserves the building's authentic daytime appearance while enabling breathtaking nocturnal transformation.

The small form factor allows installation in spaces where conventional lighting would be impossible or visually disruptive, ensuring seamless integration with delicate architectural details.

2. Swift, Non-Invasive Installation:

Recognizing the sensitivity of historic structures, these lights are designed for remarkably easy and secure installation. They typically feature robust, corrosion-resistant mounting brackets (often stainless steel or high-grade alloy) specifically shaped to clip or screw securely onto the underlying roof battens or purlins beneath the tiles.

This method eliminates the need for destructive modifications like drilling through precious historic tiles or complex structural alterations. Installation is faster, cleaner, and significantly reduces the risk of accidental damage to the building fabric.

Pre-wired connectors and clear installation guides further streamline the process, minimizing on-site labor time and complexity, a crucial factor in heritage sites with access restrictions.

3. Inherent Safety Engineered for Sensitive Structures:

Safety is non-negotiable, especially near historic, often combustible materials like aged timber. LED corrugated lights are fundamentally safe:

Low Voltage Operation: Primarily designed for safe, efficient 12V or 24V DC systems, drastically reducing electrical shock hazards and fire risk compared to line-voltage alternatives.

Exceptional Thermal Management: The high-quality aluminum die-casting isn't just durable; it acts as an integral heat sink. This design efficiently draws heat away from the densely packed LED chips and drivers, preventing dangerous heat buildup that could damage surrounding materials or degrade the fixture itself. Surface temperatures remain low to the touch.

Robust Sealing & Protection: The IP65, IP66, or higher rating signifies complete protection against dust ingress and powerful water jets from any direction. This is critical for enduring harsh weather conditions on exposed rooftops.

Impact Resistance: The die-cast aluminum housing provides excellent mechanical strength, protecting against accidental impacts or environmental stresses.

This inherent safety profile provides immense peace of mind for architects, conservators, and building managers responsible for protecting invaluable heritage assets.

4. Superior Value Proposition (Cost-Effectiveness):

While the initial investment might be comparable to some alternatives, the true value (high cost-performance ratio) shines over the lifespan:

Exceptional Energy Efficiency: Utilizing the latest generation LEDs, these fixtures consume a fraction of the power required by halogen or incandescent equivalents, leading to substantial savings on electricity bills, especially for large-scale or all-night illumination projects.

Extraordinary Longevity: With rated lifespans often exceeding 50,000 hours (potentially over 11 years of continuous operation), maintenance costs plummet. The need for frequent bulb replacements and associated access equipment/scaffolding – a major expense and disruption on historic sites – is virtually eliminated.

Reduced Maintenance Burden: The combination of long life, robust construction (die-cast aluminum, high IP rating), and stable performance due to the filling process minimizes downtime and maintenance interventions.

This long-term operational efficiency translates to a significantly lower Total Cost of Ownership (TCO), making it a financially astute choice for both large institutional projects and smaller heritage renovations.

5. Aesthetic Versatility & Custom Solutions:

Far from a one-size-fits-all solution, LED corrugated lights come in a wide array of styles and configurations to meet diverse architectural and design needs:

Stealth/Linear: Ultra-slim, minimalist bars focused purely on discreet uplighting.

Decorative Housings: Options with subtly textured or colored housings that can complement specific tile colors or architectural styles when a minimal view is unavoidable.

Beam Angles: Available in various beam spreads (narrow spot, medium flood, wide flood) to precisely control light distribution, from grazing individual tile textures to washing broad roof planes.

Color Temperatures: Choices ranging from warm white (2700K-3000K) to enhance the warmth of brick and wood, to neutral white (4000K) for a cleaner, more contemporary feel, often selectable per project.

Color Changing (RGB/RGBW): For dynamic architectural statements or seasonal displays, programmable options are available.

Custom Lengths: Many manufacturers offer bespoke cutting or specific lengths to perfectly match the module spacing of different tile types or roof sections.

This versatility ensures architects and lighting designers can find or specify the perfect fixture to achieve their desired aesthetic outcome while respecting the building's character.

Delving Deeper: The Technical Features Explained

1. Advanced LED Light Source: The foundation of the corrugated lamp's performance lies in its use of new-generation, high-efficacy LEDs. These solid-state light sources are inherently:

Energy-Saving: Converting significantly more electrical energy directly into light (lumens) rather than wasted heat (watts), drastically reducing power consumption.

Environmentally Friendly: Containing no hazardous mercury or lead, coupled with low energy use, resulting in a much smaller carbon footprint. Their long lifespan also reduces waste compared to frequently replaced traditional bulbs.

Exceptionally Long-Lived: Rated for 50,000+ hours of operation, ensuring years of reliable service with minimal lumen depreciation when properly thermally managed.

2. Premium Die-Cast Aluminum Construction: The housing isn't merely a shell; it's a critical functional component:

Material Superiority: High-pressure die-casting using quality aluminum alloys results in a housing that is incredibly strong, rigid, and resistant to corrosion from rain, pollution, and salt spray (crucial for coastal heritage sites).

Optimal Heat Dissipation: Aluminum's excellent thermal conductivity is harnessed fully. The housing is designed with substantial thermal mass and often incorporates intricate finned structures or optimized surface area to maximize heat transfer from the LEDs and driver into the surrounding air. This exceptional heat dissipation performance is the single most critical factor in ensuring LED longevity, maintaining stable light output (minimizing lumen depreciation), and preserving color consistency over time.

3. Full Filling Process (Potting/Encapsulation): This is a vital manufacturing step often overlooked but crucial for reliability:

Process: After assembly, the internal cavity containing the LED module, wiring, and driver components is completely filled with a thermally conductive but electrically insulating silicone compound or epoxy resin.

Benefits:

Enhanced Thermal Management: The potting compound improves heat transfer from the electronic components to the aluminum housing, further aiding overall thermal performance.

Superior Moisture & Contaminant Protection: Creates a hermetic seal, preventing any internal condensation, water ingress (even beyond the IP rating of the housing seals), dust, or corrosive gases from damaging sensitive electronics. This is vital for longevity in harsh outdoor environments.

Mechanical Stability & Vibration Resistance: Encapsulates components, preventing movement, micro-vibrations, or loosening of connections due to wind, thermal cycling, or minor impacts. This significantly improves shock and vibration resistance, ensuring long-term performance stability.

Protection from Corrosion: Seals components away from atmospheric oxygen and pollutants, preventing internal corrosion.

4. Purpose-Built Application: The design intent is crystal clear:

Precise Light Casting: These fixtures excel at casting light onto the specific surfaces they are designed for – the distinctive undulating curves of glazed tile corrugated surfaces, the majestic slopes of ancient architectural towers, and the intricate patterns of landmark tile work on palaces, temples, or historic civic buildings.

Highlighting Architectural Form: By positioning light sources discreetly below the ridge line, they create a striking grazing effect that emphasizes the texture, depth, and unique three-dimensional form of tiled roofs and architectural elements, transforming them into illuminated sculptures at night.

Preservation-Centric: Every aspect – from the non-invasive mounting and low heat emission to the absence of UV/IR radiation damaging to historic materials – aligns with best practices in heritage conservation lighting.

| Specification: |

|

|---|

| Model No.: | LY - WLD - 7005A |

| Power: | Single color: 3W, RGB/RGBW: 3x2W |

| Voltage: | DC24V |

| Led Chips Qtys: | 3PCS |

| Beam Angle: | 15°/ 20°/ 30°/45°/60°/ 15x45°/10x60°/20x40° |

| Control: | ON - OFF/DMX512 |

| Product Size: | L125xH80MM |

| Specification: |

|

|---|

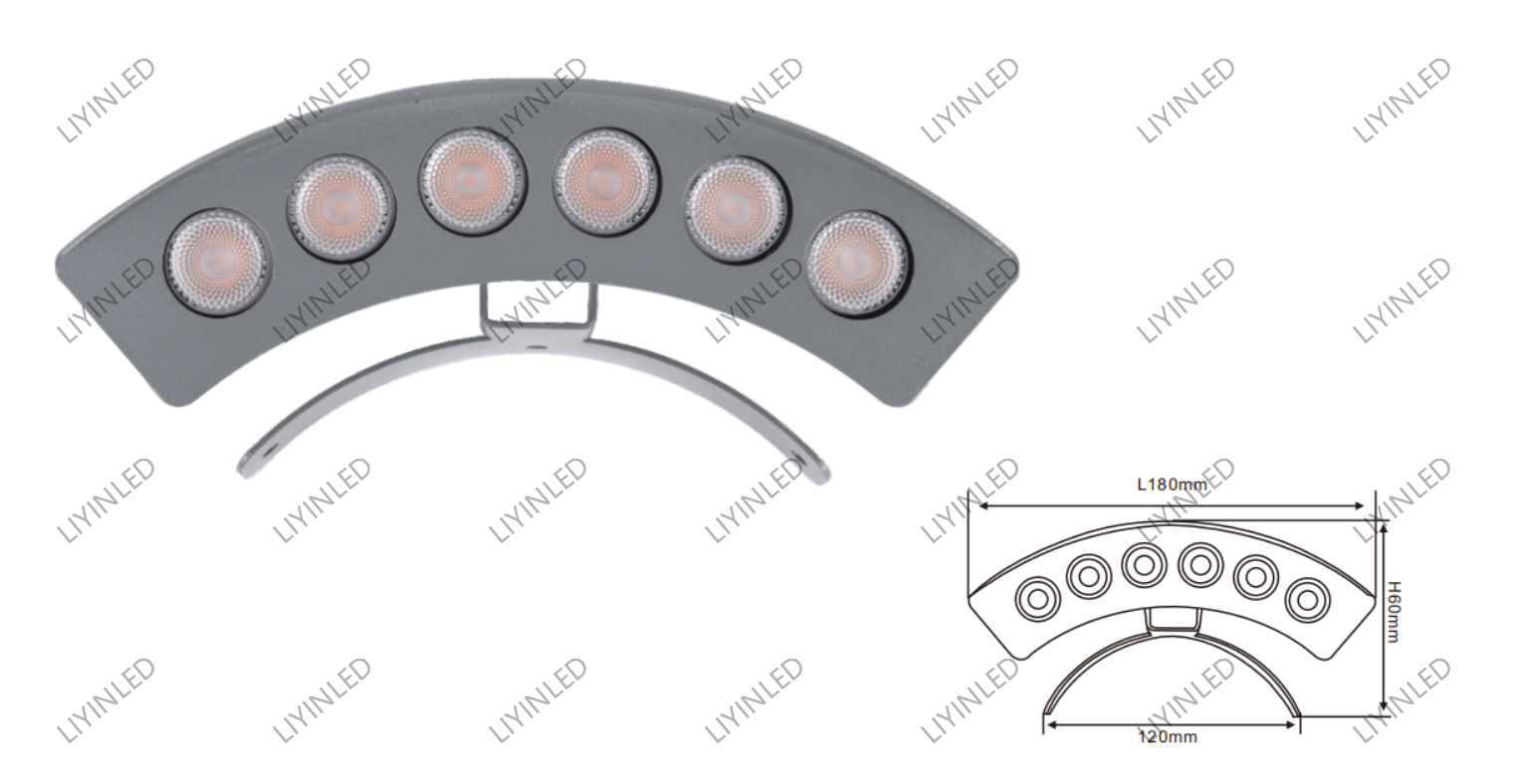

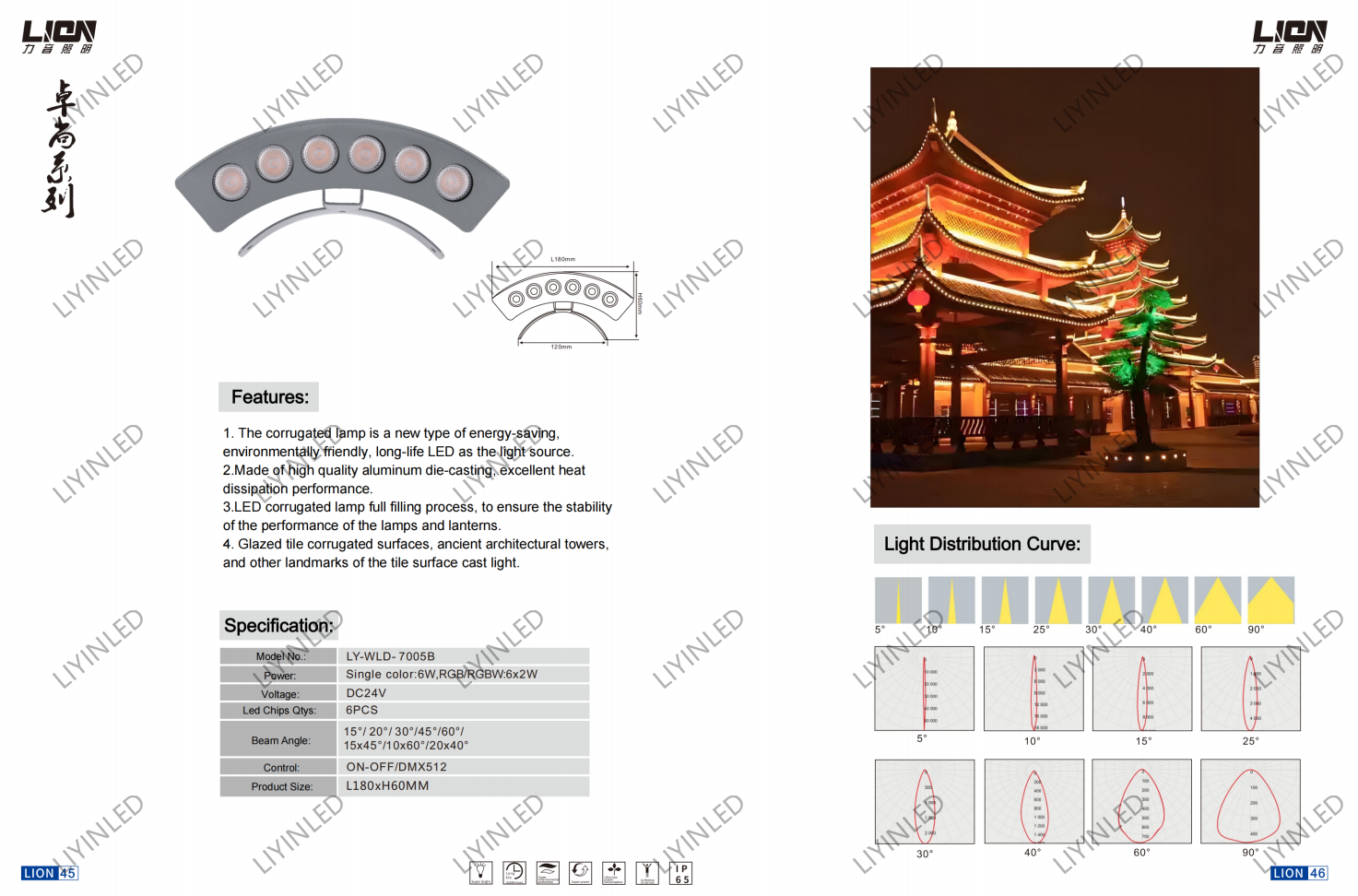

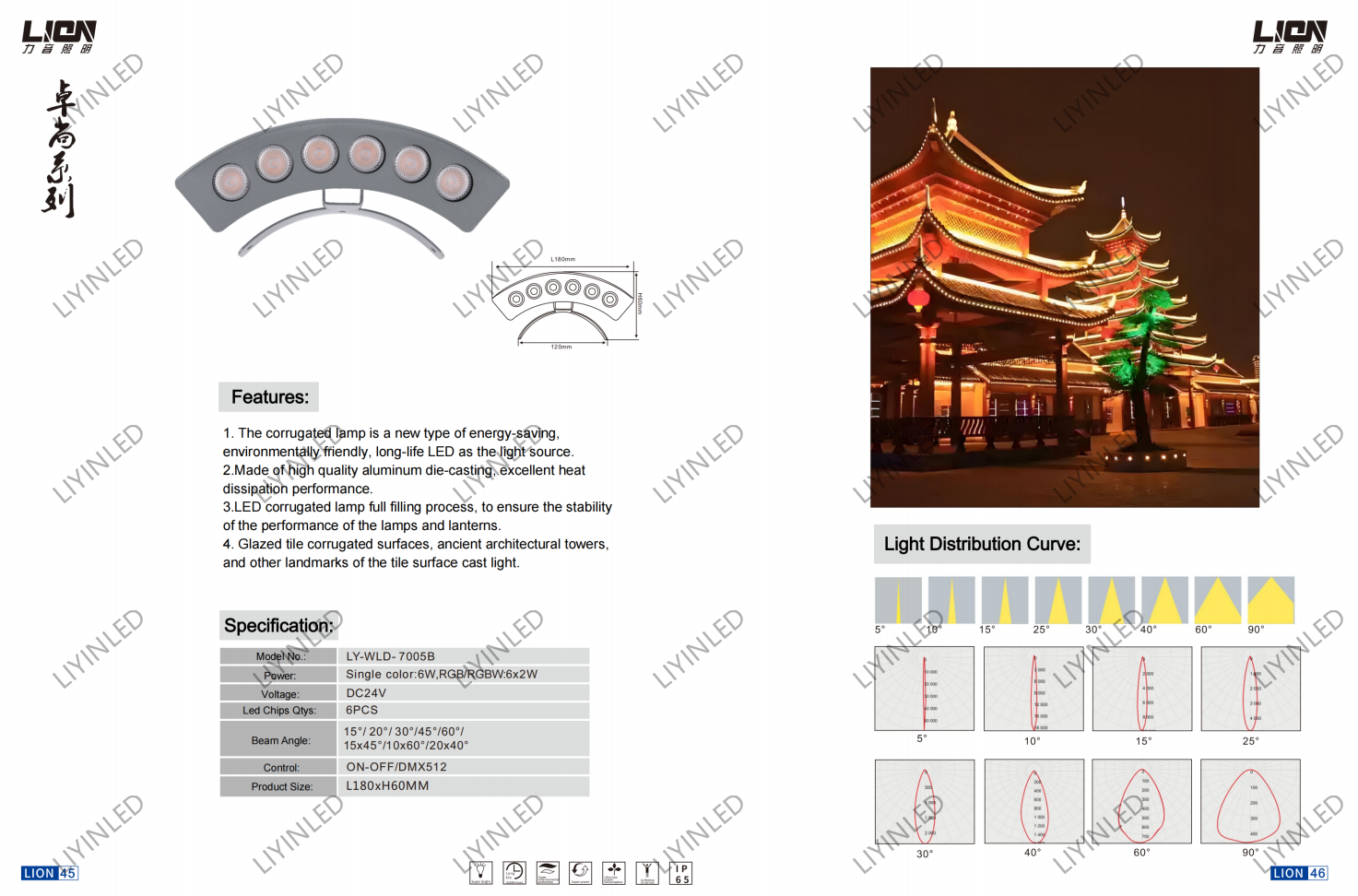

| Model No.: | LY-WLD-7005B |

| Power: | Single color: 6W, RGB/RGBW: 6x2W |

| Voltage: | DC24V |

| Led Chips Qtys: | 6PCS |

| Beam Angle: | 15°/ 20°/ 30°/ 45°/ 60°/ 15x45°/ 10x60°/ 20x40° |

| Control: | ON-OFF/DMX512 |

| Product Size: | L180xH60MM |

| Specification: |

|

|---|

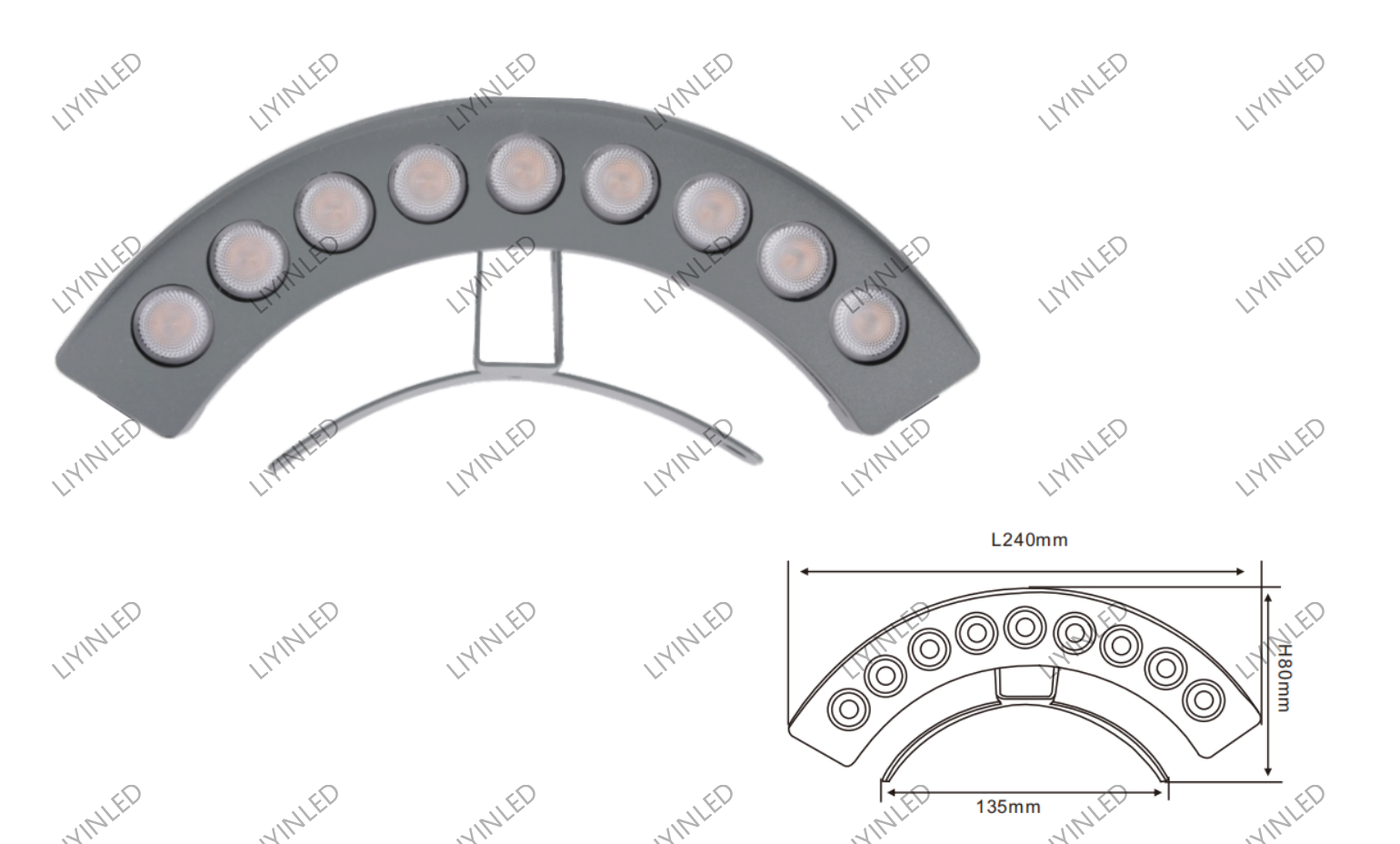

| Model No.: | LY-WLD-7005C |

| Power: | Single color: 9W, RGB/RGBW: 9x2W |

| Voltage: | DC24V |

| Led Chips Qtys: | 9PCS |

| Beam Angle: | 15°/20°/30°/45°/60°/15x45°/10x60°/20x40° |

| Control: | ON-OFF/DMX512 |

| Product Size: | L240xH80MM |

The LED Corrugated Tile Light represents a sophisticated fusion of advanced lighting technology and heritage-sensitive design. Its compact, discreet form allows for magical illumination without compromising historic integrity. Installation is simplified and non-destructive, respecting the fabric of cherished buildings. Engineered with premium materials and processes such as die-cast aluminum and full potting, it delivers unparalleled safety, reliability, and longevity in challenging environments. The exceptional energy efficiency and minimal maintenance requirements translate into outstanding long-term value. Finally, the wide range of available styles and configurations empowers designers to achieve the perfect aesthetic harmony for any tiled or historic structure. For illuminating the intricate beauty of corrugated tiles, ancient towers, and landmark facades, the LED Corrugated Light is not just a product; it's the essential, purpose-built solution for the discerning conservator and architect.