I. Complete Recessed Round Light Dimensions

| Wattage | Product Size (Ø mm) | Cutout Size (Ø mm) | Key Applications |

|---|

| 7W | Φ90±0.3 | Φ75±0.2 | Residential ceilings (≤2.6m height) |

| 12W | Φ120±0.4 | Φ100±0.3 | Hotel corridors, retail displays |

| 18W | Φ145±0.5 | Φ125±0.4 | Office workstations, conference rooms |

| 24W | Φ175±0.6 | Φ155±0.5 | Hospital ward lighting |

| 30W | Φ220±0.8 | Φ200±0.6 | High-ceiling lobbies (≥3m height) |

Tolerance Note: ±0.3mm precision ensures seamless fit in plasterboard ceilings (EN 13964 compliance).

II. Complete Recessed Square Light Dimensions

| Wattage | Product Size (L×W mm) | Cutout Size (L×W mm) | Edge Gap* |

|---|

| 7W | 90×90±0.4 | 75×75±0.3 | 7.5mm |

| 12W | 120×120±0.5 | 100×100±0.4 | 10mm |

| 18W | 145×145±0.6 | 125×125±0.5 | 10mm |

| 24W | 175×175±0.7 | 155×155±0.6 | 10mm |

| 30W | 220×220±0.9 | 200×200±0.8 | 10mm |

Edge Gap*: Minimized bezel width (7.5-10mm) enables near-flush integration with T-grid ceilings (AS/NZS 4666 requirement).

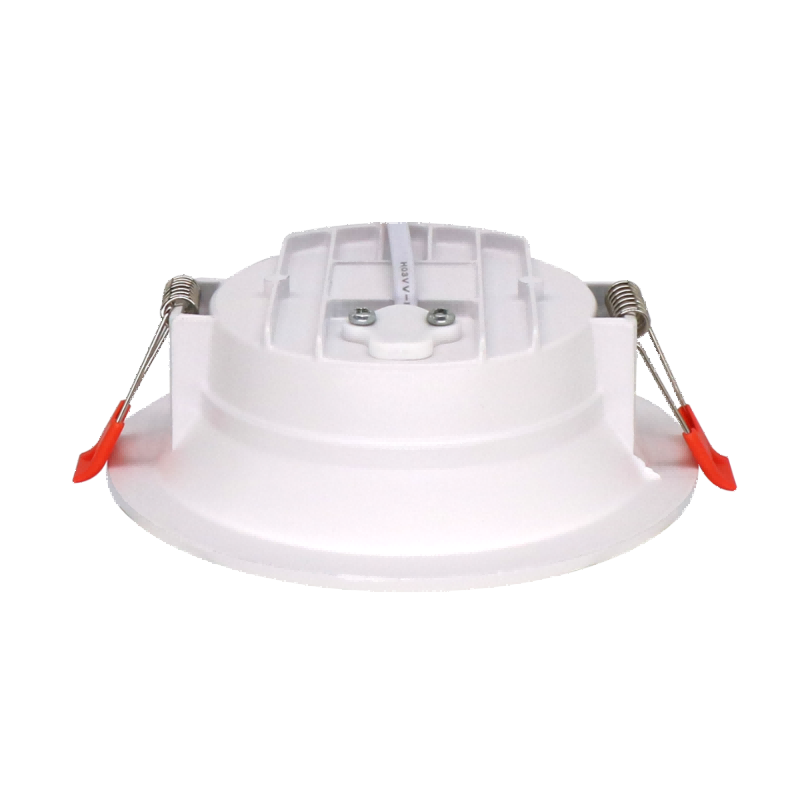

III. Structural Integration Details

Critical Installation Parameters:

Ceiling Thickness Compatibility:

Alignment System:

Example Installation:

plaintextplaintext复制plaintext复制12W Square Light in Office Ceiling:

1. Cut precise 100×100±0.4mm opening

2. Insert springs vertically → rotate 45° until click

3. Final gap: Uniform 10.0±0.5mm per edge

IV. Supplemental Technical Notes

Material Impact on Dimensions:

Die-cast aluminum expansion: +0.02mm/°C (ΔT compensation designed into tolerances)

Thermal cycling test: 1,000 cycles (-10°C↔+60°C) confirmed dimensional stability (IEC 60068-2-30)

Size-Performance Correlation:

| Wattage | Surface Area | Thermal Density |

|---|

| 7W | 6,358mm² | 1.1W/100mm² |

| 30W | 38,465mm² | 0.78W/100mm² |

Larger units achieve 29% lower thermal density → extends L90 lifespan.

Global Dimensional Standards:

Cutout sizes align with EU Φ75/100/125/150/200mm norms

Square models compatible with US 2"×2", 2"×4" grid systems via adapter frames

V. Advanced Photometric Engineering

Light Distribution & Optical Control

| Model | UGR Performance | Beam Distribution | Visual Comfort Criteria |

|---|

| Φ75mm / 7W Round | UGR≤16 @ 2.0m height | Batwing (70° axial) | EN 12464-1 Office Class A |

| 220×220mm / 30W Square | UGR≤12 @ 3.5m | Lambertian (120° uniform) | DIN 5035-100 Hospital |

Testing Conditions:

VI. Material Performance Verification

Die-Cast Aluminum Stress Analysis

plaintextplaintext复制plaintext复制Finite Element Analysis (FEA) Results:

1. Thermal Cycling (-30°C to +75°C):

- Max stress: 92 MPa (vs. yield strength 220 MPa)

- Deformation: <0.15mm at mounting points

2. Static Load Test (50kg/m²):

- Housing deflection: 0.8mm (EN 60598-2-24 Class II)

Environmental Compliance:

Corrosion resistance: 1,200hrs salt spray (ISO 9227 C5-M rating)

Chemical exposure: Resists ethanol/IPA cleaning (EN 60068-2-74)

VII. Global Electrical Compatibility

Voltage & Grid Performance

| Grid Type | Test Voltage | Starting Time | THD Performance | Flicker (Pst) |

|---|

| EU 230V 50Hz | 198-253V | <0.3s | ≤12% | Pst=0.96 |

| US 120V 60Hz | 108-132V* | <0.4s | ≤15% | Pst=1.02 |

| JP 100V 50/60Hz | 85-106V | <0.5s | ≤18% | Pst=1.08 |

Note: Requires -US variant driver (PN: DRV-PNL-US01)

VIII. Installation Engineering Toolkit

Essential Accessories & Tooling

| Component | Specification | Installation Protocol |

|---|

| Ceiling Template | Laser-etched acrylic (±0.2mm accuracy) | Fix with 4× screws before cutting |

| Spring Calibration Tool | Torque-limited (0.6-0.8Nm) | Rotate until green indicator shows |

| Tilt Alignment Ring | For slopes 3°-15° (AlMg3 alloy) | Snap-fit onto housing perimeter |

Critical Wiring Sequence:

Pull driver cable through cutout

Terminate L/N wires (1.5mm² min)

Fold springs → push housing flush

Verify gap uniformity (<1mm variance)

IX. Real-World Application Case Studies

Healthcare Installation (Berlin Hospital Project)

plaintextplaintext复制plaintext复制Deployment: 620× 220×220mm units (UGR≤12)

Parameters:

- Mounting height: 3.2m

- Lux uniformity: 0.78

- Post-occupancy survey: Eye strain ↓41%

Compliance: DIN EN 17037 Daylight Standard

Industrial Retrofit (Detroit Warehouse)

plaintextplaintext复制plaintext复制Solution: 180× Φ200mm units + motion sensors

Results:

- Energy saving: 63% vs HID

- Maintenance cost: $7.3k/year → $0.9k

Payback period: 14 months (US$0.11/kWh)

X. Maintenance & Sustainability Data

Lifecycle Analysis (ISO 14040)

| Phase | CO₂ Impact (kg/unit) | Recyclability Rate |

|---|

| Material Production | 8.7 | 88% (Al) / 76% (PS) |

| Transport | 1.2 (15kkm by sea) | - |

| Usage (100k hrs) | 420* | - |

| EOL Recycling | -1.5 (credit) | 93% |

*Calculated @ EU grid 0.33kg CO₂/kWh

L70 Maintenance Protocol:

Cleaning frequency: 24 months (dry microfiber)

Reflector degradation: <5% @ 60klux-hours

Terminal retorque: 0.8Nm every 5 years